The new ODW 1736/60 throughfeed press line from the Freudenstadt-based mechanical engineering specialist Robert Bürkle GmbH has been in use at the Swiss company Argolite AG in Willisau for laying HPL (high pressure laminate) on carrier boards for around a year now. And this system has been running like Swiss clockwork from day one. We spoke to Hanspeter Walker, Head of Production at Argolite AG, about the company's goals and the role played by the system from Freudenstadt.

Around 90% of sales are generated in its home country of Switzerland, with the remaining 10% coming from neighboring countries. In order to stay one step ahead of the competition, Argolite is showcasing innovative product surfaces and decors, for example. Coatings with UV protection, particularly high scratch resistance or antibacterial properties are a matter of course. The issue of sustainability is becoming increasingly important. Energy for process heat is generated from a pellet heating system, supplemented with pellets from HPL production waste. The PV installation on the hall roofs generates over one million kWh of electrical energy for the operation of the production facilities. "It goes without saying that customers are always offered the highest quality at the usual market price. In addition, we can score points with a delivery speed of a maximum of ten days for all products and are also able to offer our customers panels in batch sizes of one. This is where other suppliers often have to pass," emphasizes Hanspeter Walker.

In Switzerland, as everywhere else in the world, the market has changed. Argolite is mainly active in the contract business and supplies HPL for hospitals, schools, kindergartens, retirement and nursing homes, public buildings and residential complexes, for example. Sales are largely handled by the wood-based materials trade, but advice is provided by the company's own staff directly on the market to decision-makers such as architects, planners, engineers and building owners. The HPL panels are in turn processed by carpenters or interior fitters.

One line, exactly as required

This is exactly where the new through-feed press line from Bürkle comes into play, because the use of the new production line means that today's speed and flexibility in production is now also possible when applying HPL to carrier boards. Axel Mayer, Head of Project Management Press/Laminating, was responsible for the planning and development of the line at Bürkle.

"Although the structural conditions had to be created first, it quickly became clear that the 45-metre-long, 12-metre-wide and 4-metre-high system had to be adapted to the new spatial conditions. This was a challenging task. Two halls were demolished and rebuilt, which now house the system and were integrated directly into production," explains Axel Mayer. It was precisely these structural requirements that were one of the reasons why the purchase of such an occupancy system was delayed for so long at Argolite and was put on hold again for the time being in 2014. The current planning for the construction of the production line began in 2018 - the order was then placed in 2020. From Hanspeter Walker's point of view, one argument was decisive for Argolite: there is only one point of contact for the entire system and everything is supplied from a single source!

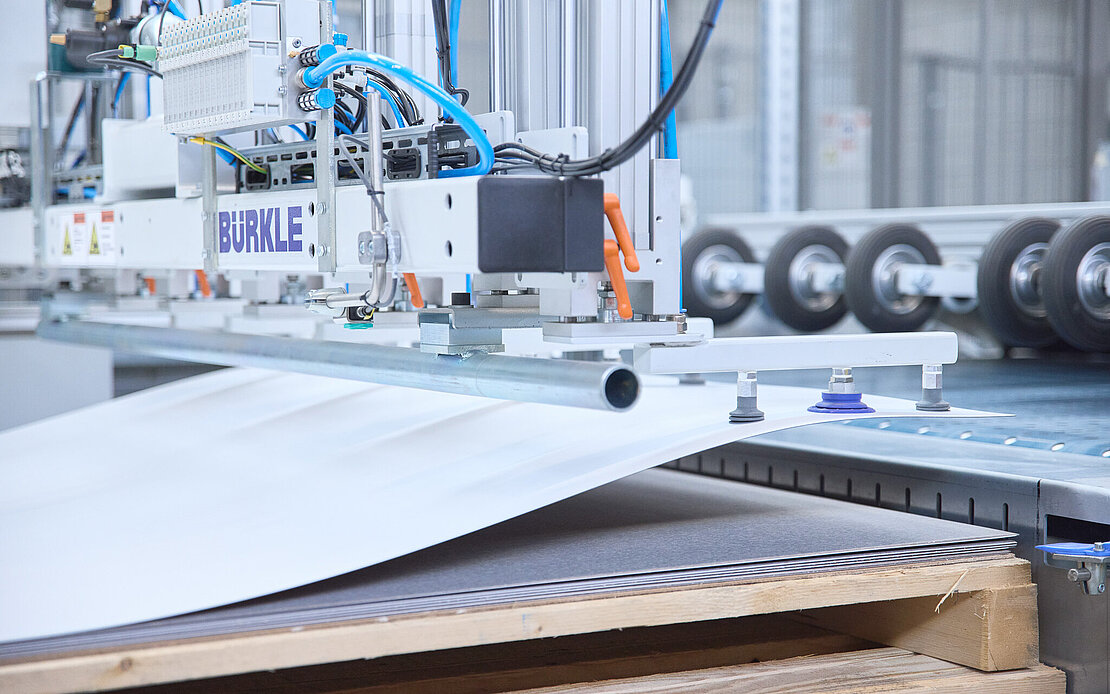

Today, chipboard is mainly used in Willisau. Occasionally, however, gypsum fiberboard, plywood or other substrate materials are also used. One prerequisite is that the carrier boards and the laminates can be sucked in with a vacuum. The largest carrier boards measure 3,300 x 1,600 mm, the smallest formats 2,000 x 600 mm, but even smaller parts can be covered manually. The press processes laminates in thicknesses from 0.5 to 1.9 mm and generates a specific pressure of 60 N/cm2 in relation to the maximum pressing surface at a pressing temperature of up to 110 degrees. The standard thickness of HPL is 0.9 mm. The workpiece is finished in just over 2.5 minutes, i.e. it has been fed in, placed on a carrier and the four edges have been trimmed.

One machine, two gluing techniques

The heart of the system is, of course, the press. Argolite realized the very special requirement of installing two gluing systems side by side. One roller coating machine can be used to process dispersion glue (PVAc glue), while the other uses a PUR hot melt adhesive. The second important requirement was to be able to run batch sizes of one economically with the application system, to be able to process small parts manually or - if required - to go into large-scale production. Argolite has never been designed for maximum output, but for variety and consistently high quality. In order to be able to realize a batch size of one in production without changeover times, a data record is transferred from the higher-level control system for each individual carrier panel and each laminate and tracked through the system with the respective panel.

"All these requirements were implemented with the Bürkle system to our complete satisfaction," says the production manager happily. In the processing method with PVAc glue, the panels are covered on both sides (top and bottom). If PUR glue is used, one side is covered. If both sides of the carrier board are to be covered, a second pass of the boards is required.

In November, an update for the data interface was integrated into the system. This was developed together with a software manufacturer and now forms a bridge between the ERP system and the system control. The advantage is that it is now possible to react even faster to customer requirements and convert the system accordingly.

The Bürkle machine is operated by two employees. One of the employees is responsible for feeding and control, the second for picking the carrier boards. Both employees were involved right from the start and were able to accompany the installation of the machine from September 2022 and get to know how it works live. In principle, the employees work intuitively on the system, as many processes are self-explanatory, i.e. learning by doing.

After a year of trouble-free operation, Hanspeter Walker's summary is correspondingly positive: "With the new occupancy system, we have become even more reliable for our customers and have been able to increase our capacities and quality at the same time. We were particularly impressed by the fact that all our requirements and wishes were integrated into this system and that it now literally runs like Swiss clockwork. This is exactly how we envision the partnership with our machine supplier."