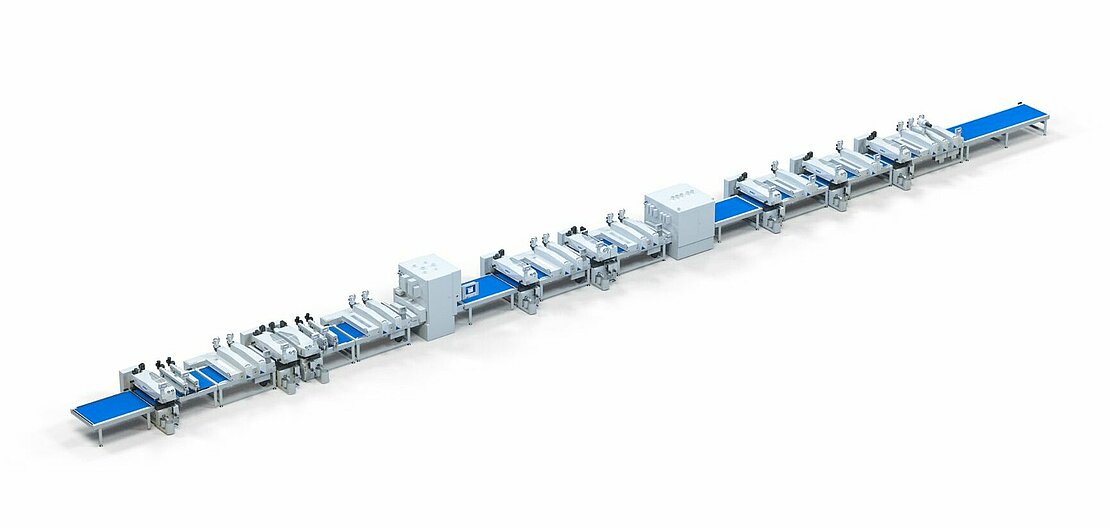

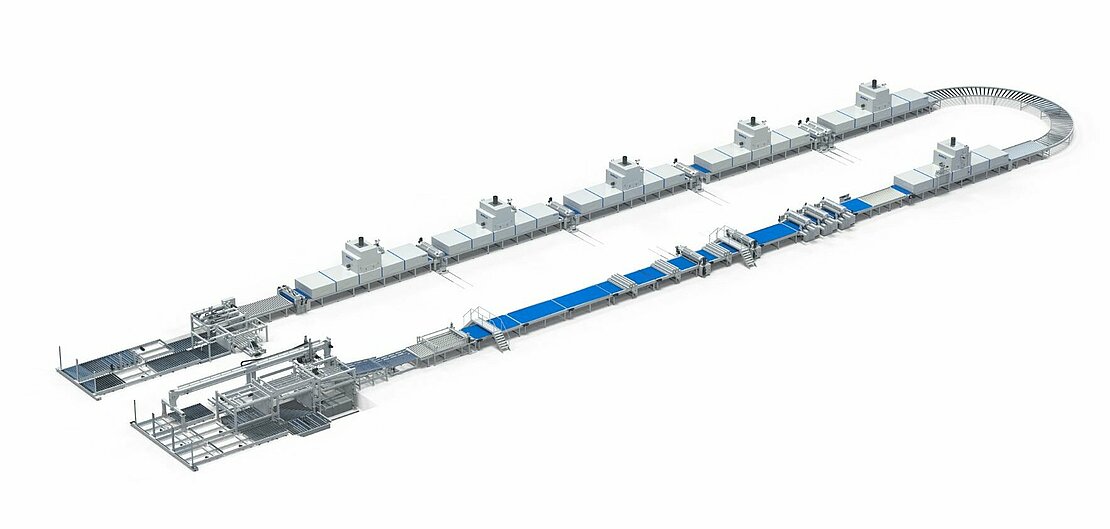

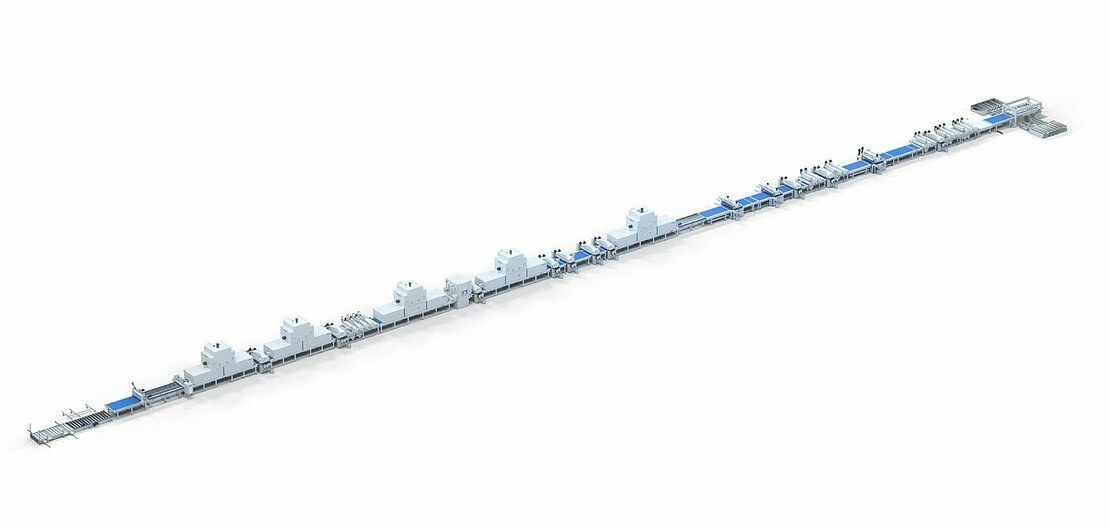

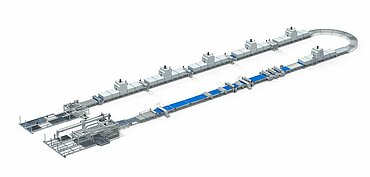

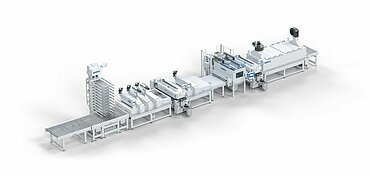

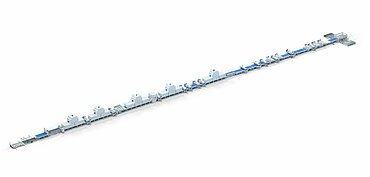

Roller coating lines

Thought out to the smallest detail: BÜRKLE roller coating lines

While the wishes and design requirements of your customers are subject to constant change, the demands on your end products remain the same: perfection down to the smallest detail. With our roller coating machines, we at BÜRKLE offer our customers various technologies and customer-specific line concepts for the coating of their end products in the best possible quality. In combination with our handling and drying systems, our customers benefit from complete lines from a single source, which is the result of detailed process knowledge in coating technology.