Flooring - Parquet

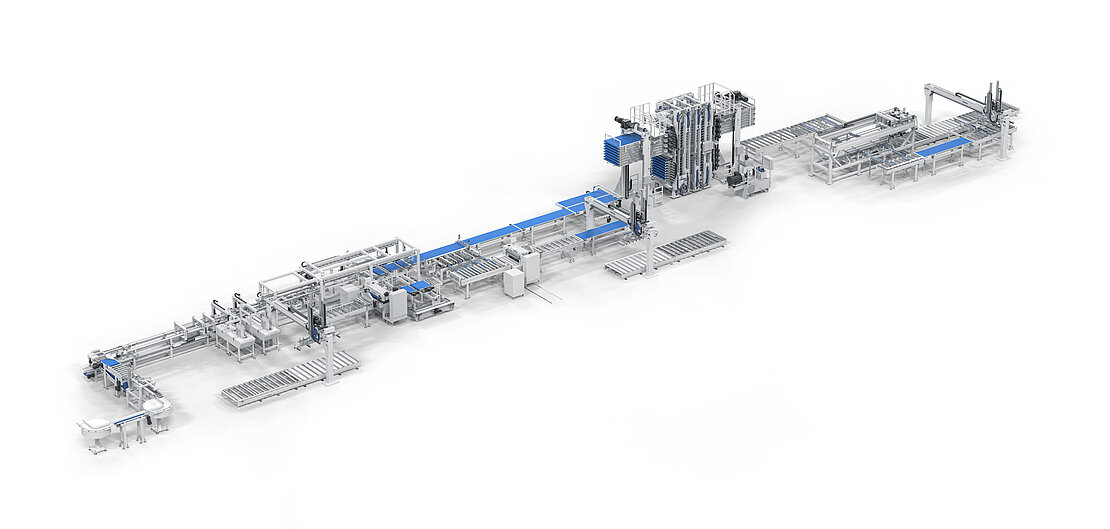

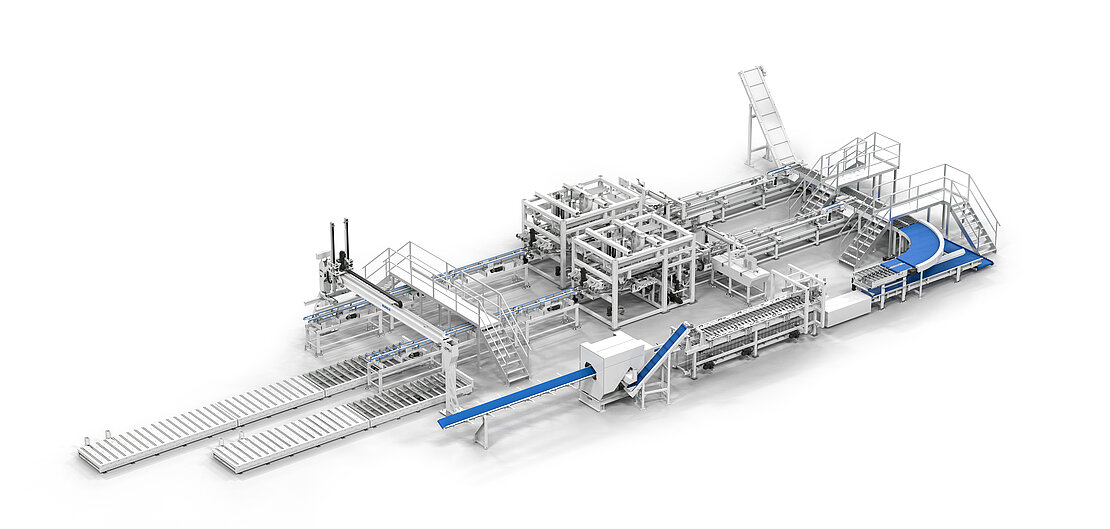

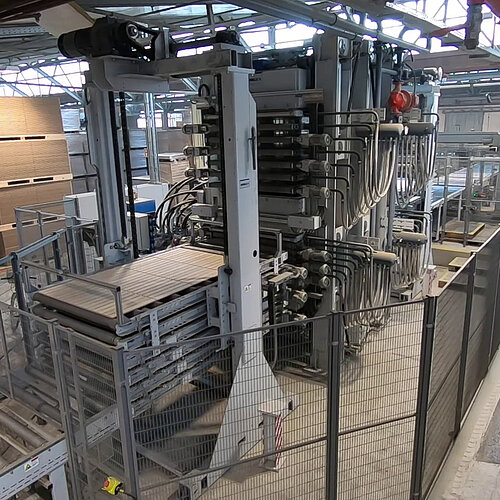

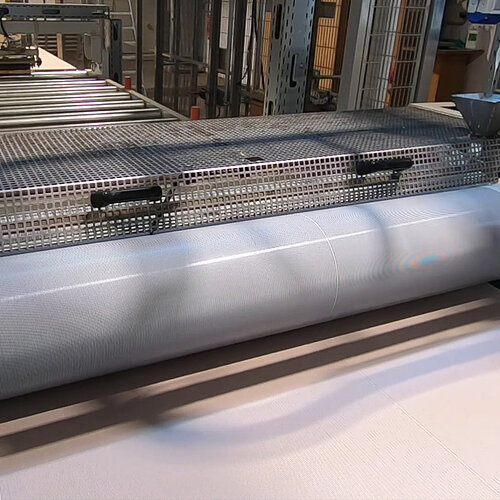

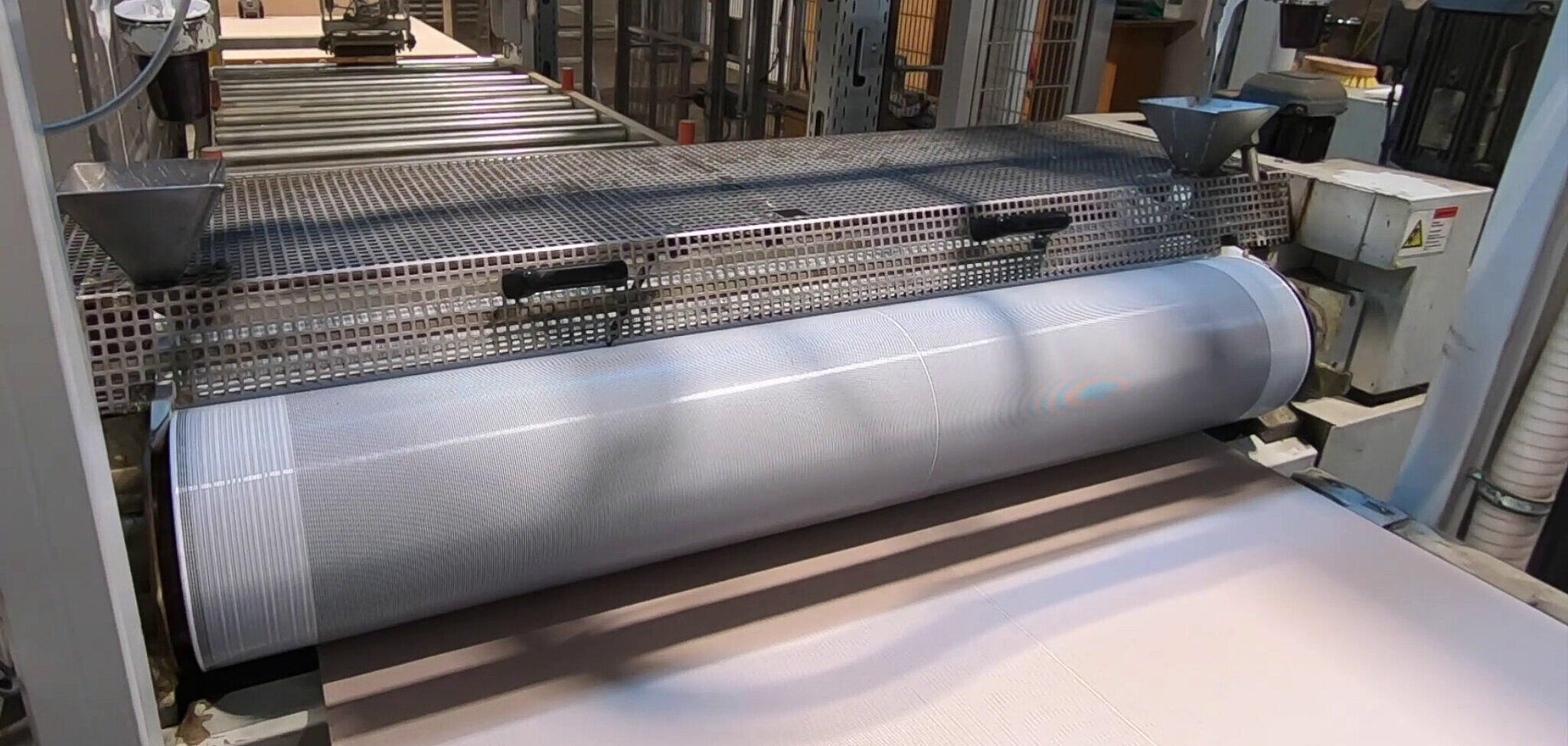

Parquet production: Press lines that set standards

The natural material wood tends to change depending on temperature and weather conditions due to its ability to adapt to its environment. For this reason, different construction types and production methods have always been used to compensate for the natural behavior of wood. As one of the pioneers in the development of fully integrated press lines, we are aware of these challenges in parquet (engineered flooring) production, and our lines enable top quality for two- or three-layer parquet.