Upon entering the production hall, the sheer size of the so-called XPS downstream line is particularly striking. The total throughput length of the U-shaped system is around 250 meters, with a width of 14 meters. The cooling section alone is over 100 meters long up to the first knife, on which the extruded strand cools down to processing temperature and gains strength.

After the internal commissioning at the Bürkle site in Mastholte, the individual machines of the line were transported to Austria on around 30 trucks, where they were mechanically and electrically installed and commissioned in just over three months. It took around 19 months between the first quotation drawing and the delivery of the plant. A special feature was that the entire coordination and technical clarification between the client and contractor had to take place almost exclusively via video meetings due to the corona pandemic, reports Oliver Plümpe, Project Manager for insulation lines at Bürkle.

Expandable if required

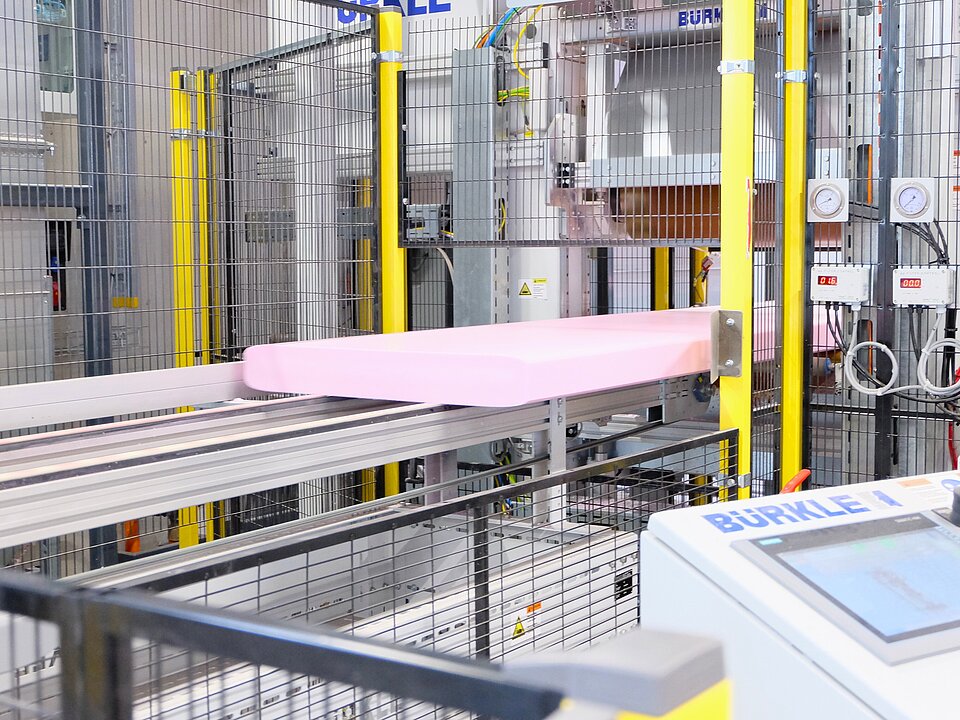

The machine, which was designed precisely according to customer requirements, can process extruded panels up to a length of 3,200 mm, a width of 800 mm and a maximum thickness of 240 mm. Like all systems in the modular system, this machine can also be expanded on a modular basis. By retrofitting additional modules, such as a thermobonding station, the system can even be extended to a sheet thickness of up to 400 mm.

As the system produces around the clock, i.e. the edges are processed and the boards are cut to length and stacked, a very high number of high-quality insulation boards made from extruded XPS are produced each month. “The special feature of the machine is clearly the high output rate of several tons of material per day in combination with extremely high accuracy and quality,” describes Plümpe. It takes around one and a half hours from the time the material leaves the extruder to the packaging of the finished insulation boards.

In order to give the maximum-thickness boards sufficient time before final processing, the system has cooling towers, which in turn contributes to the high dimensional accuracy and quality of the end products. The cooling towers, also known as paternosters, are very energy-efficient and accurately positioned thanks to their lightweight construction.

Naturally, the responsible Austrotherm employees were trained by the Bürkle fitters in the handling of the system components, their control, possible troubleshooting as well as mechanical and electrical maintenance and servicing. As usually only very experienced employees work on the machine, the training was carried out within a week as part of the trial production. “Our effective all-round service naturally also includes the option of remote access and remote maintenance should unexpected problems occur,” emphasizes Plümpe.

“We have been working with Bürkle for over 30 years at some of our sites. All components are perfectly matched to each other and the machines are particularly impressive due to their robustness and reliability. In our eyes, Bürkle has a clear technological edge, especially in the area of digitalization, and impresses with its excellent customer service,” says Dr. Heimo Pascher, Managing Director of the Austrotherm Group, describing the successful collaboration.

Sustainability as a program

The Austrotherm Group actively strives to be a pioneer in sustainability and environmental protection and invests annually in the continuous improvement of the goals it has set itself in order to become Europe's most sustainable insulation manufacturer by 2030.

One reward for this commitment is, for example, the award for the XPS site in Purbach from Fraunhofer Austria and Industriemagazin in the “Factory of the Year” competition as the most sustainable production facility in Austria. “The fact that we won the 'Green Factory' category and can call ourselves the most sustainable production facility in Austria makes us very proud,” says a delighted Dr. Pascher.

Further awards, such as the best insulation supplier from the Association of Austrian Building Material Dealers in 2024 and the repeated award from the construction magazine Solid in 2023, confirm the quality and customer focus of the family business.

“To be the best in the market, you also need the best partners. With Bürkle as the supplier of our machine, we have created an important basis for achieving our goals of maximum sustainability and quality in the long term,” concludes Sebastian Horvath, Plant Manager in Purbach.