When selecting their technology partner, Vicaima relies on a proven partner: Vicaima has maintained a decades-long partnership with Robert Bürkle GmbH from Freudenstadt. A first large system was installed in 1998. In the early 1990s, Bürkle had already partially automated machines that were largely operated manually at Vicaima. The door manufacturer repeatedly expands the production capacities of its location to ensure safe and rapid delivery of its markets in high quality. Since mid-2022, an additional innovative Bürkle system has been working at the Vale de Cambra headquarters for door production. "We have known and appreciated our contacts at Vicaima for many years. We always work together openly and trustingly. Exchange with technology and production management, represented by Filipe Ferreira and Nuno Pinho, is always connected with the question 'What's new?'. But their request for a new system surprised us," says Bürkle project manager Carsten Henkenjohann, smiling.

DIN A4 wishlist for door system

On a sheet of paper only DIN A4 in size, the business partners from Portugal had written down their wishes for the new system. Henkenjohann was confronted with the question 'Can you implement this for us?' The core wish sounded logical and simple: Vicaima wanted to combine as many processes as possible in an inline system for door production. Usual upstream or downstream processes had to be integrated into a process while maintaining the highest possible flexibility. The same applied to the diverse frame inserts, which had never before been supplied to a production facility in this form and scope and had to be assembled there. The integration into the inline process was also on the wish list.

From just over 62 cm² to 1800 m²

An intensive German-Portuguese cooperation began. From the very beginning, the Bürkle team relied on high engineering competence and the comprehensive collection of structured data sets along the desired process chain. They recorded upstream processes such as frame construction, deck plate cutting, continuous gluing of door inserts, and other production steps in data sets. The data obtained was integrated into the infeed and outfeed of the system and visualized in an easily understandable way for the operators on HMI dashboards. In highly concentrated and harmonious cooperation, they made progress step by step. The communication within the individual groups was not always easy due to the COVID-19 pandemic and the associated restrictions on travel and meetings. "However, a great trust between our teams and a high common demand for the desired solution allowed us to grow together and ultimately find a convincing result," summarizes Henkenjohann the working atmosphere.

From the development of the requirements specification to the production of the individual components by Bürkle, and the installation and commissioning of the complex system in Vale de Cambra, it all started on a DIN A4 sheet. Today, Carsten Henkenjohann, his Portuguese counterpart Nuno Pinho, project manager of the Vicaima team, and José Caetano, head of maintenance and on-site coordinator, are proud of the success of the entire team. From the DIN A4 sheet, a complex inline system was created on a good 1800 m².

The inline concept is right

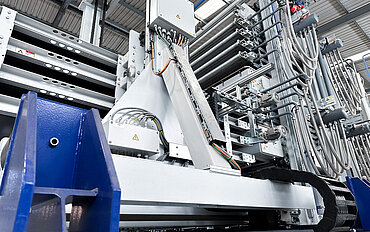

The Vicaima plant produces exclusively three-layer doors, consisting of an insert, frame, and two cover plates. The main product are high-performance doors in various classes, which are individually certified for the respective markets. The inline solution jointly designed by the project teams is convincing. Depending on the function and protection class of the doors, various inserts are used. The tightness between the insert and the frame wood is particularly demanding. The system allows for continuous bonding of the inserts, their precise cutting, the management of leftover pieces in the system, and quick deployment when needed. Digitally controlled bolt magazines (virtual magazines) allow for a variety of combinations and, if necessary, small series. The combination options stored in a database can retrieve the bolts necessary for the respective assembly in the process. All bolts can be assembled inline.

Various types of cover plates can be fed into the system. In addition to standard raw materials, coated and uncoated plates - thin, thick, heavy, and light - are also used. All types can be cut to length or width in the process. The one-sided top adhesive process is absolutely clean. Therefore, there are no contamination or maintenance problems in the system. The door blank laying system is also highly flexible and can "swallow everything." The final process steps are the pre-press, especially for the possible production of honeycomb doors, and the classic Bürkle presses with a capacity of four doors per minute. Then, the doors are cooled and stacked.Various types of cover plates can be fed into the system. In addition to standard raw materials, coated and uncoated plates - thin, thick, heavy, and light - are also used. All types can be cut to length or width in the process. The one-sided top adhesive process is absolutely clean. Therefore, there are no contamination or maintenance problems in the system. The door blank laying system is also highly flexible and can "swallow everything." The final process steps are the pre-press, especially for the possible production of honeycomb doors, and the classic Bürkle presses with a capacity of four doors per minute. Then, the doors are cooled and stacked.

Competence convinces

"Our engineering competence is deeply rooted in the company's DNA. This enables us to offer our market partners a diverse range of customized solutions," says Bürkle Managing Director Olaf Rohrbeck. He is convinced that Bürkle has been able to establish a very good market position with a range of highly individualized and technically demanding door systems, especially in the last five years. The system realized together with Vicaima is a prime example of a high-performance door production system in the industrial sector for Rohrbeck. The range of Bürkle door systems extends from batch size-1 solutions to mass production models. One of the specialties of the Bürkle engineering team at the Mastholte location are systems with a high degree of automation and intelligent detail solutions. This allows users a great deal of flexibility with high output. They gladly accept corresponding tasks on just one sheet of paper.