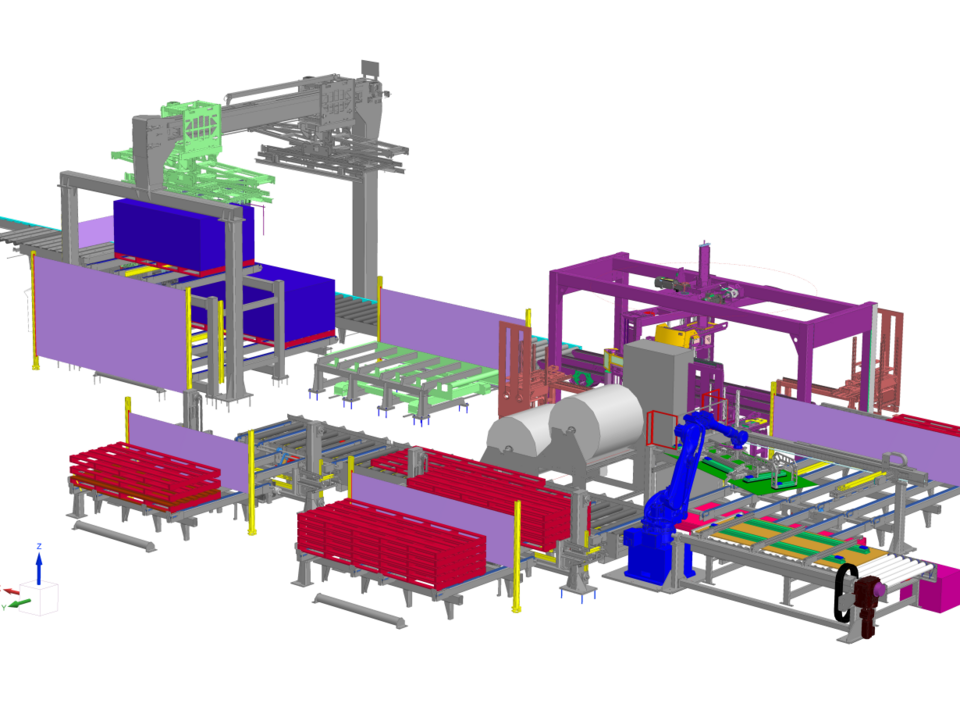

A few clicks, then the robot picks up one of the facade elements that has left the coating system, turns it and transports it towards the destacker. An error message then appears indicating that the holding force has been exceeded. In reality, the panel weighing around 80 kilograms would now fall to the floor unchecked. However, Marian Michels, programmer at Robert Bürkle GmbH, has recently been able to investigate and rectify such errors on a digital model: A digital twin supports him and his colleagues in development and design. The basis is the CAD model of the system as a “ Single Source of Truth”, as the basis for all subsequent steps, as Jürgen Müller, Head of Mechanical Design at Bürkle, explains.

What sounds very theoretical at first becomes clear when you look at the market environment of Robert Bürkle GmbH: The company is a pioneer in the field of coating technologies in many industries and applications. The spectrum of products ranges from credit cards, printed circuit boards and photovoltaic modules to furniture and wooden components. “This diversity presents us with the challenge of having to implement and further develop a large number of processes and system concepts,” Müller continues. Most of the systems are individually tailored to specific customer requirements. Bürkle must provide and maintain the corresponding know-how for commissioning and service for its users worldwide. For this reason, the design management team initiated the first approaches to develop and commission systems on a model some time ago.

“This allows us to make better use of our resources in programming on the one hand, and to design and fine-tune the systems more efficiently on the other,” says Müller.

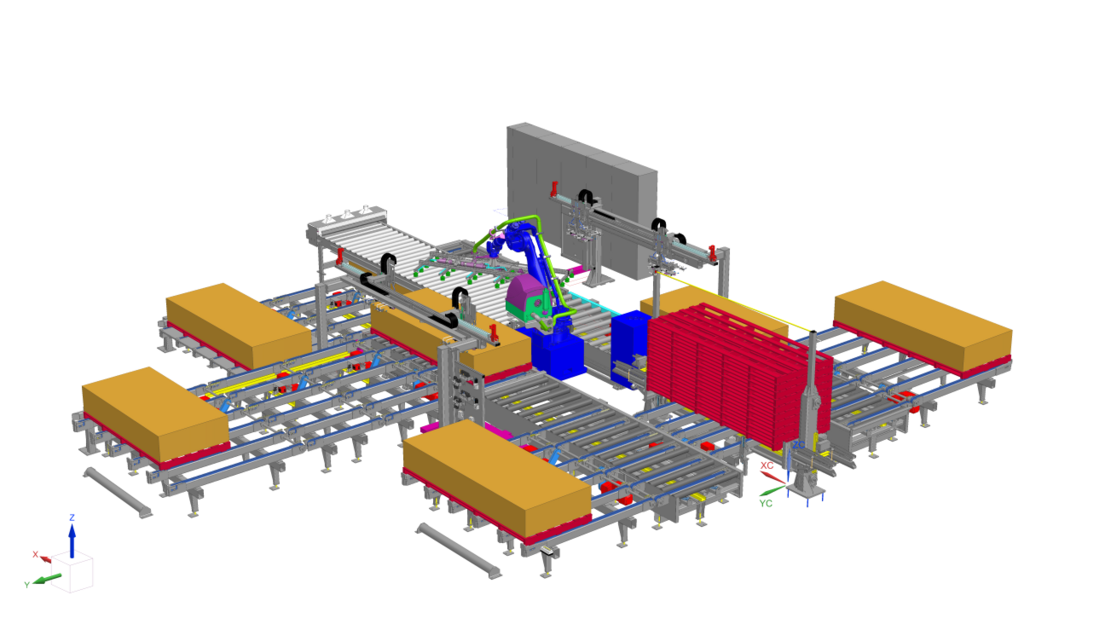

There were two impulses that gave virtual commissioning a major boost at Bürkle: An extensive customer project that presented itself as a pilot project for virtual commissioning and the end-to-end tool chain from Siemens. The cooperation was based on partnership and Bürkle was able to present virtual commissioning at “Ligna”. Müller continues: “The solution for the digital twin that Siemens presented to us was a very good fit with our existing tool landscape.” The integrated tool chain, with the “NX Mechatronics Concept Designer” for the mechatronic development, “Simit” for the simulation of the automation application and “PLCSim Advanced” as a virtual image of the “Simatic” controller that will later be used in reality, works perfectly with the engineering in the “Tia” portal. This eliminates unnecessary system breaks and Bürkle can integrate the new tools more easily into its development processes. The aim is for every developer to be able to carry out virtual commissioning - “we don't want to have an expert, we want to use the digital twin in our day-to-day work.” Thanks to the seamless interaction of the Siemens software tools, Bürkle does not have to enter data multiple times.

As a programmer, Marian Michals was responsible for the first implementation of the digital twin - and had to deal with two projects at once: firstly, the preparation of the showcase for the trade fair, and secondly, the virtual and ultimately real commissioning of a complex system used to paint façade elements. “The crux of the customer project was that the panels have very special material properties. That's why we used a robot with a specially designed holding device.” For the trade fair presentation, the virtual commissioning also had to “look good” as a showcase for the company's expertise. However, Michels was able to count on the support of Siemens for both topics: “We worked very well together, both during the project and afterwards - we didn't have to explain much, the colleagues from the Siemens Application Center (APC) knew what was important to us and supported us very well, especially with the kinematization.” Shortly before the trade fair, there was even time to enhance the presentation with videos and demos - “that was really fun.”

The “acid test” for the digital twin was then the virtual commissioning of the customer project. The task here was to integrate the robot into the PLC program, including testing the correct functionality and work areas. Using the model, Michels was able to detect problems at an early stage and adapt the program accordingly. He benefited from the fact that he was able to use the new standardized interface (“SRCI” Standard Robot Command Interface) between the robot and the PLC with the “Simatic Robot Integrator (SRI)”. Thanks to the SRI, the sequence can be programmed in the PLC simply, quickly and without extensive robot expertise. Thanks to the international standard, different robot manufacturers can be integrated without having to adapt the program.

Siemens and, in this case, Yaskawa as the manufacturer of the robot used, developed the interface together accordingly. This made it easy to integrate the robot into the system simulation and the real system - “the prerequisite for us to be able to implement the solution so quickly with a robot and combine virtual commissioning with robotics,” says Marian Michels.

Nevertheless, the project was under enormous time pressure - and virtual commissioning proved its worth here too: application engineers at Siemens supported the development team at Bürkle. The results were then verified and tested on the model in advance. This allowed the team to concentrate on the technologically demanding processes involved in separating and stacking. Jürgen Müller is certain: “The schedule for the project was ambitious and only became possible thanks to the use of virtual commissioning.”

The effect of virtual commissioning was enormous, especially when integrating the robot into the stacking process with complex movement sequences and challenging spatial conditions. Not least because the tests with real material on the system were more efficient, adds Marian Michels: “The plates are three meters long and over a meter wide. You can imagine the effort involved in reloading the system for a trial.” What's more, Michels was able to supervise a large part of the commissioning virtually from the office. This not only saves Bürkle travel costs: “A journey of 500 kilometers for commissioning also means that developers then spend five hours in the car. With the digital twin, many things can be tested in advance and the effort required for real commissioning is significantly reduced. This means that working time can be used more sensibly,” explains Müller. Overall, he estimates that the efficiency gains could amount to up to 30 percent in terms of the scarce and expensive resources in software development.

For Jürgen Müller, there is therefore no question that Bürkle will continue to work with the digital twin. The development team is also enthusiastic about the new possibilities: “Our colleagues are literally on fire.” The same enthusiasm could also be felt among many visitors at “Ligna”, Müller continues: “The feedback from our long-standing customers in particular was: we'll do the next project like this.” This shows that new technologies can quickly gain a foothold in the timber industry: “Our users know and see the challenges that complex systems with long start-up times entail. That's why the demand for digital solutions like this will simply come.” New opportunities are now also opening up for Bürkle, Müller continues: “We may soon be able to commission the entire plant virtually and then go directly to commissioning on site with the fully tested components.” According to Müller, software development used to be heavily dependent on the imagination of the software engineer: “With the digital twin, things are different now.”

In the meantime, further projects have been implemented in practice and support from Siemens has been needed less and less. Robert Bürkle is now ideally equipped for the future commissioning of large customer-specific systems and is even more competitive.